Nate • 13 May 2025

This is a subtitle for your new post

Abstract This case study examines the challenges and failures associated with Variable Refrigerant Flow (VRF) HVAC systems in high-rise condominiums. It highlights the importance of adhering to industry association standards, manufacturers’ installation instructions, and regular maintenance schedules. The study also discusses common site observations and design considerations for VRF system piping, emphasizing the consequences of inadequate piping support.

Introduction

Variable Refrigerant Flow (VRF) systems are increasingly used in high-rise condominiums for their efficiency and scalability. Despite their advantages, improper installation and maintenance can lead to significant challenges and system failures.

Industry Association Standards

The industry standards for VRF systems are set by organizations such as AHRI and ASHRAE. AHRI Standard 1230-2021 and 1230-2023 outline the performance rating of VRF systems. ASHRAE provides guidelines on the design, installation, and commissioning of VRF systems.

Manufacturers’ Installation Instructions/Requirements

Manufacturers like Hitachi, LG, Trane, and YORK provide detailed installation guides and technical catalogs for VRF systems. These documents emphasize the importance of proper installation practices, including adequate space for units, weight support, ventilation, and leveling.

Maintenance Schedules and Requirements

Regular maintenance is crucial for the longevity and efficiency of VRF systems. This includes semiannual maintenance such as changing filters, cleaning coils, checking refrigerant charge, and inspecting refrigerant lines. Some manufacturers and service providers suggest quarterly maintenance to ensure optimal performance.

Common Site Observations

- Building Overview: High-rise condominium complex with multiple VRF systems.

- Maintenance History: Maintenance began in December 2020, focusing on outdoor units (ODUs), heat recovery units (HRUs), and common area indoor units (IDUs). The history of the equipment is unknown.

- Equipment Age: Manufactured in 2017.

- Control System: A proprietary system that manages all VRF systems.

- Piping Configuration: Rooftop system piping installed below ODUs.

- Visible Installation Issues:

- Missing Inverted Oil Traps: Pipe lengths that exceed the maximum 6.6 feet without required inverted oil traps, risking oil circulation issues and potential compressor and board failures.

- Inadequate Piping Support: Rooftop piping lacks proper support, leading to sagging, bending, and potential leaks.

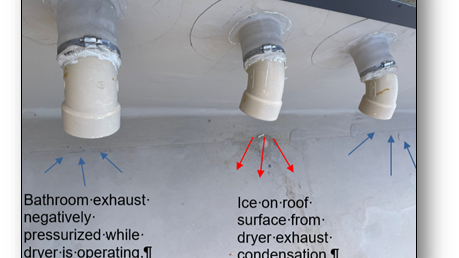

- Inadequate or failed pipe insulation: Piping lacks proper insulation, leading to condensation problems, system inefficiencies, and potential leaks.

- Incorrect Copper Linesets: Soft copper pipes used where hard drawn copper is recommended, risking damage to HRUs.

- Inadequate Indoor Lineset Support: Linesets supported with zip ties, which do not provide sufficient support.

Design of Piping System for VRF Systems

Designing the piping system for a Variable Refrigerant Flow (VRF) system is a critical aspect that impacts the efficiency, performance, and longevity of the system. Here are the key considerations:

· Pipe Lengths and Sizing: The maximum allowable vertical distance between an outdoor unit and its farthest indoor unit is typically around 150 feet, and the maximum permissible vertical distance between two individual indoor units is approximately 45 feet. The maximum actual refrigerant piping lengths allowable between outdoor and farthest indoor units can be up to 490 feet. Pipe diameters should be selected based on the system’s capacity requirements and the manufacturer’s specifications.

· Expansion and Contraction Loops: Due to temperature variations, refrigerant pipes can expand and contract. To accommodate this, expansion loops or offsets are used. These loops allow for the natural movement of the pipes without causing stress or damage.

· Oil Traps: In VRF systems, only inverted oil traps are allowed. Oil traps are crucial as they prevent oil from getting trapped in the system, which could lead to compressor bearing losses and system inefficiency.

· LATS Program: The LG Air Conditioning Technical Solution (LATS) program is often used during installation to ensure accurate system design. It helps in calculating refrigerant piping diameters, refrigerant quantities, and piping lengths based on the selected model and user-typed distance.

· As-Built Drawings and Calculations: After installation, it is essential to provide as-built drawings and calculations. These documents should reflect the actual installed conditions of the VRF system and include details such as equipment locations, piping routes, and control strategies. They serve as a reference for future maintenance and any system modifications.

Incorporating these elements into the design of a VRF system’s piping will help ensure that the system operates efficiently and effectively over its lifespan. It’s also important to adhere to the manufacturer’s guidelines and industry standards throughout the design and installation process.

Inadequate piping support in HVAC systems can lead to a range of serious issues. Here are some of the consequences:

- Leaks and Cracks: Excessive stress on the pipes due to inadequate support can cause leaks and cracks, which may lead to water damage and the need for costly repairs.

- Catastrophic Failures: In extreme cases, the lack of proper support can result in catastrophic failures of the piping system.

- Sagging and Misalignment: Without proper alignment and positioning, pipes can sag or become misaligned, affecting the system’s efficiency, and potentially causing further damage.

- Pooling Corrosion: Improper spacing of pipe supports can lead to sagging or drooping pipes, which in turn can cause pooling corrosion and even collapse of the pipes.

- Galvanic Corrosion: Metallic guides without lining can lead to galvanic corrosion if pipes and supports are made of dissimilar metals.

- Crevice Corrosion: Metal-to-metal contact can create small divots that house microbes, leading to crevice corrosion and eventual failure of pipes or supports.

- Metal-to-Metal Friction: This friction can wear down surfaces, weakening the pipe or support and increasing the risk of rupture.

- Noise and Vibration: Inadequate support can also lead to increased noise and vibration, which can be a nuisance and potentially cause structural damage.

-

Proper pipe support is critical for the safe and efficient operation of HVAC systems. Ensuring that installation and maintenance adhere to industry standards and manufacturers’ guidelines is essential to prevent these issues.

Conclusion

The common site observations of VRF systems exhibit several installation and maintenance issues that could lead to system failures. Adherence to industry standards, manufacturers’ instructions, and regular maintenance schedules is essential to prevent these problems and ensure the systems’ longevity and efficiency.